Pneumatic regulating valve realizes regulating function by changing the opening of the valve. The adjustment function also has requirements for response speed, accuracy, and technology. These requirements need to be achieved through pneumatic accessories, such as positioners, solenoid valves, blocking valves, amplifiers, air filter pressure reducing valves, reversing valves, etc. These pneumatic accessories are often used, but if they are used improperly, they will cause problems and fail to meet the needs of the site.

This article will give examples based on the commonly used pneumatic accessory structures for regulating valves.

Intelligent electric positioner

1) Principle

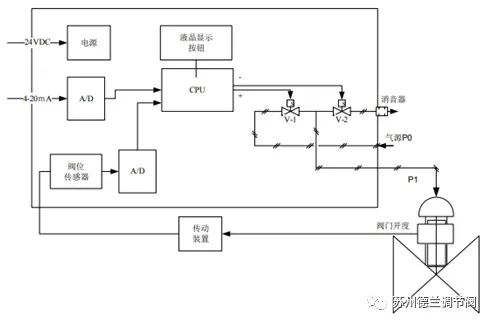

The actual opening of the valve is converted into a digital code signal by the position sensor through A/D conversion, and the input signal of the positioner is compared in the CPU to calculate the deviation between the two. If the deviation exceeds the positioning accuracy, the CPU outputs instructions to make the corresponding The opening/closing piezoelectric valve action, that is, when the set signal is greater than the valve position feedback, the boost piezoelectric valve V-1 opens, the output air source pressure P1 increases, and the increase in the pressure of the actuator chamber is the increase in the valve opening. Reduce the deviation between the two; if the set signal is less than the valve position feedback, the exhaust piezoelectric valve V2 will open, and the output source pressure P1 will be reduced through the silencer exhaust, the pressure in the actuator chamber will decrease, and the valve opening will decrease , Until the deviation value is within the positioning accuracy range, the piezoelectric valve V2 is closed and the valve is stable.

Schematic diagram of intelligent electric positioner

2) Advantages and disadvantages

The intelligent electric positioner has the advantages of high reliability, high control precision, high sensitivity, easy expansion of functions, and communication capability, and fully adapts to the requirements of the development direction of networked, integrated, and intelligent industrial control systems.

Intelligent electric valve positioners have high requirements for compressed air quality. Small particles can easily block the piezoelectric valve nozzles. Water droplets in the air will cause the piezoelectric valve to fail, and the piezoelectric valve cannot be repaired after it is damaged.

3) How to use it correctly

The debugging of the intelligent electric positioner is very simple. According to the steps in the manual, it can be automatically adjusted. Due to the complicated on-site use environment, the positioner shell screws are tightened and waterproof cable joints are used to prevent rainwater from entering the positioner. The pressure relief valve in the air supply pipeline should have a drainage function to prevent water in the air supply pipeline from entering the positioner, causing damage to the piezoelectric valve.