Suzhou Delan Energy Technology Co., Ltd.

Date: February 27, 2014

Client: Jiangsu Datang Lusigang Power Plant End User: Jiangsu Datang Lusigang Power Plant

Quotation number: Contract number:

Contact:

Project Name: Localized Transformation of the Minimum Flow Rate of Steam-driven Feed Water Pump of Nantong Lusigang Power Plant 660000# Unit

Business letter

Thank you very much for your opportunity to provide us with this service.

We believe that the minimum flow recirculation valve of our company's feedwater pump with circulating convection structure can fully meet your requirements.

We also believe that using our company's patents, technical level and years of experience will give your company a satisfactory service.

Program content

l The structure of an imported valve

l Problems that are prone to occur in an imported valve

l Problem analysis of an imported valve

l An import valve design problem

l Circulating convection disc technology

l Repair the original valve case

l Cases of reforming the original valve

l Scope of supply

1. The structure of an imported valve

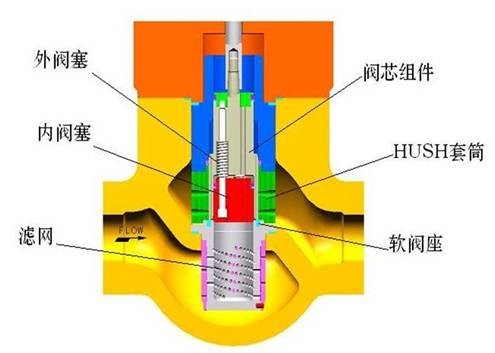

1. Principle

After the fluid first passes through the filter screen to filter the scum and depressurizes, it depressurizes through the gradually staggered semicircular flow channel in the HUSH sleeve.

2. Advantages

Using a combination of soft and hard sealing surfaces, there are two seals composed of 4 sealing surfaces, and the sealing effect is good.

3. Disadvantages

a. The structure is complex and requires high processing accuracy; b. Smaller dross will flow into the valve core through the filter screen, causing the valve core and sleeve to jam.

c. The screws inside the valve core are easily broken due to vibration.

d. In the working condition of higher pressure difference, the depressurization effect is not good, and it is easy to produce cavitation at the valve core.

Second, the problems that are easy to occur in an imported valve

1. The spool is strained or stuck 2. The bolt is broken 3. The filter is cavitation

4. HUSH sleeve cavitation 5. Valve core assembly cavitation 6. Soft valve seat erosion

7. Valve body erosion

3. Analysis of an imported valve problem

1. The spool is strained or stuck: This structure is more complicated, with many parts, resulting in larger accumulated errors and prone to jamming; the complex structure requires more precise fit tolerances, and the filter screen has 60 wires. In other words, for the inner parts of the valve core, the filter screen does not play a filtering role. Therefore, the valve core is easily strained and stuck.

2. Bolt fracture: After the bolt is connected by thread, it is welded by electric welding. After welding, the stress cannot be released, and the bottom diameter of the thread is small. The valve core expands during the use of the valve, causing the thread to break at the root. In addition, the high pressure difference of the minimum flow valve is also a cause of thread breakage.

3. Filter cavitation: The filter is a combination of two layers of cylinders with small holes, which is only equivalent to two-stage throttling. The valve is under pressure, and the HUSH sleeve has a poor pressure reduction effect, which together lead to cavitation of the filter.

4. HUSH sleeve cavitation: Although the sleeve has six layers, it is nominally 6-level depressurization, but the principle of depressurization is that one layer of sleeve covers half of the small holes of the other layer of sleeve, which basically cannot reduce the pressure. The effect of pressure, so the sleeve cavitation and erosion are also understandable.

5. Cavitation of the valve core assembly: due to the poor pressure reduction effect of the sleeve, cavitation occurs at the gap between the valve core and the sleeve, resulting in cavitation damage to the outer circle of the valve core and the inner circle of the sleeve.

6. Erosion of the soft valve seat: The soft seal has low hardness. If a little scum is stuck on the seal, internal leakage will occur and the soft seal will soon be damaged.

7. Valve body erosion: When the valve leaks inside, it cannot reduce the pressure, and the high pressure difference directly acts on the valve body, and the valve body erosion phenomenon will occur.

Fourth, a certain imported valve design problem

The inner diameter of the 4" valve seat of a certain imported minimum flow valve used in 300,000 units is 60mm and 79mm, but the inner diameter of the 6" minimum flow valve seat used in 600,000 units is only 60mm, that is, the 6" valve body is installed. For 4" internals, only the CV value of the valve is taken into consideration, and the flow velocity and the number of pressure drop stages of the high pressure difference through the valve are not taken into account. Therefore, the minimum flow valve used in 600,000 units or higher units has more problems.

5. Circulating convection disc technology

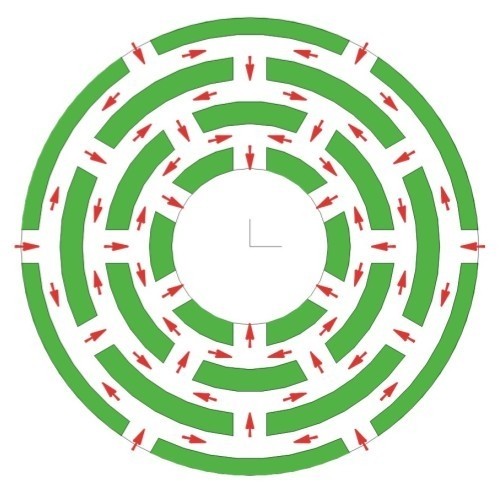

1. Principle:

After the fluid flows into the disk, it hits the disk wall and splits into two. At this time, the energy of the fluid is consumed when impacting and changing direction; then one of the fluids collides with the opposite fluid and changes the speed, which consumes energy again at this time . The above two processes are one cycle, and after a plurality of the above cycles, the effect of reducing pressure and decelerating is achieved.

2. Calculation formula

Among them: v—disc exit speed (m/s)

△P=ρgh, pressure difference (m)

n—Number of fluid turns

3. Antihypertensive effect

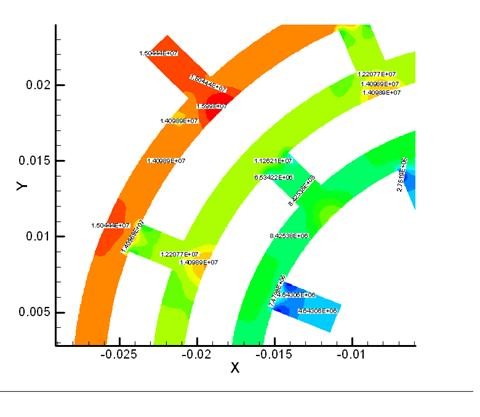

The figure on the right is the pressure distribution cloud diagram, which is simulated by fluid analysis software. From the figure, we can see that the heavy colors are high pressure (inlet pressure), and blue is low pressure (outlet pressure). The pressure distribution is gradually reduced, and will be higher when two streams of liquid collide.

4. Advantages

1) Anti-blocking:

a. The outlet cross-sectional area size of the circular convection labyrinth disc is the same as the outlet cross-sectional area size, large particles will not enter, and small particles will not get stuck in the flow channel.

b. The flow channel in the disc is circular, and there is no dead zone at the corners, which ensures that impurities will not accumulate and cause long-term blockage.

2) Anti-scouring

a. After the multi-stage pressure reduction and deceleration of the circular convection labyrinth disc assembly, the speed of the flow through the sealing surface is controlled at 20-30m/s for liquid and 80-100m/s for gas.

3) Low noise

After the fluid passes through the disc multi-stage pressure reduction and deceleration, the speed of the fluid flowing through the disc hole and the valve seat is reduced, and the fluid noise is also reduced.

5. Main application occasions

l Feed water pump outlet circulation valve

l Boiler feed water regulating valve

l Desuperheating water regulating valve

l Boiler continuous blowdown valve and intermittent blowdown valve

l Main steam trap

l High pressure differential natural gas regulating valve

Six, maintenance case

1. Guangdong Yunfu Power Plant 300,000 units 4"-2500LB minimum flow circulation valve

2. Shaanxi Bin County Yaochi Power Plant 200,000 units 4"-2500LB minimum flow circulation valve

3. Henan Shangqiu Yudong Power Plant 300,000 units 4"-2500LB minimum flow circulation valve

4. Zhenjiang China Resources Power Plant 600,000 units 4"/6"-2500LB minimum flow circulation valve

Seven, transformation case

1. Xuzhou Pengcheng Power Plant 300,000 units 3"-2500LB minimum flow circulation valve

2. Xuzhou Pengcheng Power Plant 1 million units 6"-2750LB minimum flow circulation valve

3. North United Power Shangdu Power Plant 600,000 units 6"-2500LB minimum flow circulation valve

4. Mengneng Xilin Gol League Xilin Thermal Power Plant 300,000 units 3"-1500LB minimum flow circulation valve

5. China Resources Nanjing Chemical Park Thermal Power Plant 135,000 units 2.5"-1500LB minimum flow circulation valve

6. Guangdong Yudean Jinghai Power Generation Co., Ltd. 600,000 units 2"-1500LB desuperheating water regulating valve

8. Scope of supply

The scope of supply is shown in the table below

序号 | 名称 | 型号 | 数量(台) | 品牌 |

1 | 阀门 | MX-6"L25W1V | 1 | 德兰 |

2 | 气动执行器 | GD-44 | 1 | 德兰 |

3 | 定位器 | V18345-1010221001 | 1 | ABB |

4 | 电磁阀 | ASW 8320G174 | 1 | ASCO |

5 | 空气过滤减压器 | T50960-069-000 | 1 | MB |

6 | 放大器 | IL-100 | 1 | SMC |

7 | 限位开关 | WLCA12-2N | 2 | OMRON |